What if your favorite kitchen gadget suddenly goes silent? A dead appliance can throw your entire routine into chaos, but the fix might be simpler than you think. This guide walks you through practical steps to identify why your device isn’t powering up—without requiring advanced technical skills.

- Understanding Common Appliance Power Issues

- Initial Safety Checks and Power Supply Verification

- Appliance Not Turning On? Here's a Quick Diagnostic Guide

- Key Troubleshooting Steps for Electrical Failures

- Diagnostic Tips for Mechanical and Component Failures

- Inspecting and Testing Internal Appliance Components

- Preventative Maintenance and Regular Checks

- When to Call a Professional Repair Technician

- Conclusion

- FAQ

Many problems start with overlooked basics. Always begin by confirming the power supply is active. Check if the outlet works by plugging in another device. Inspect the cord for damage and ensure it’s securely connected. If the outlet is dead, your circuit breaker or fuse box might need attention.

Safety is critical. Unplug the appliance before inspecting it, and avoid water contact. For gas-powered units, shut off the gas line first. Your owner’s manual often holds clues—refer to its troubleshooting section for model-specific advice.

This guide covers both electrical glitches (like tripped breakers) and mechanical failures (such as jammed parts). You’ll learn when a DIY fix is safe and when to call a professional. Let’s get your home back on track.

Key Takeaways

- Always start with power source checks: outlets, cords, and circuit breakers.

- Prioritize safety by unplugging devices before inspection.

- Consult your appliance’s manual for tailored solutions.

- Identify common electrical issues like blown fuses or tripped breakers.

- Know when to attempt repairs yourself and when to seek expert help.

Understanding Common Appliance Power Issues

Nothing halts productivity like a device that refuses to start. Before diving into complex repairs, learn to recognize patterns that signal power-related failures. Many symptoms are easy to spot once you know what to look for.

Identifying Symptoms of a Power Failure

If your unit shows no lights, sounds, or display activity, you’re likely dealing with an electrical issue. Intermittent operation—like a dryer that runs briefly then stops—often points to faulty wiring or overloaded circuits. Buzzing noises or burning smells demand immediate attention to prevent hazards.

Overview of Common Electrical and Mechanical Faults

Electrical problems frequently involve damaged cords, tripped breakers, or worn-out switches. For mechanical failures, a stuck motor in your dryer or a seized compressor could be the culprit. Always make sure to test outlets with another device during peak time to rule out grid fluctuations.

Your appliance’s manual often explains error codes or suggests reset procedures. Check power settings—some units have child locks or sleep modes that mimic total shutdown. If basic troubleshooting doesn’t resolve the issue, contact a licensed technician before handling internal parts.

Initial Safety Checks and Power Supply Verification

A silent kitchen companion can disrupt your entire day. Before diving into complex diagnostics, start with these foundational steps to rule out simple causes. Safety and methodical verification are your best tools here.

Ensuring a Secure Power Connection

First, confirm the device is plugged in firmly. Wiggling cords can loosen connections over time. Test the outlet with a lamp or phone charger to check for power flow. If other devices work there, focus on the appliance’s cord for fraying or damage.

For larger units like dryers, ensure 240-volt outlets are functioning. Use a voltage tester if available. Avoid using extension cords for high-wattage equipment—they often can’t handle the load.

Inspecting Circuit Breakers and Fuses

Head to your electrical panel. A tripped circuit will show a breaker midway between on/off positions. Flip it fully off, then back on. For fuses, look for cloudy glass or broken filaments inside.

If breakers trip repeatedly, you might have an overloaded circuit or faulty heating element. Refer to your manual for recommended amperage limits. Never replace a fuse with a higher-rated one—this risks fire hazards.

When basic troubleshooting tips don’t resolve the issue, it’s wise to contact professional help. Persistent electrical problems often require expert assessment to prevent further damage.

Appliance Not Turning On? Here’s a Quick Diagnostic Guide

Discovering your essential home device unresponsive can spark instant frustration. Let’s break down advanced checks beyond basic power tests to pinpoint hidden issues.

Start by examining fuses and breakers. A tripped circuit often points to overloaded systems. Reset the breaker firmly, but if it trips again, consult a technician. For older units, replace blown fuses with matching amperage ratings—never improvise.

Inspect outlets for scorch marks or loose plugs. Use a voltage tester to confirm proper grounding. Moisture exposure near water sources can corrode connections—dry the area thoroughly before retesting.

Clogged vents or obstructions in dryers disrupt airflow, triggering safety shutoffs. Clear lint from the drum and exhaust ducts monthly. Check the door seal for gaps that strain motors.

Your manufacturer’s website provides diagrams for locating components like thermal fuses or control boards. Compare these to your unit’s layout when testing service parts. Worn belts or cracked rollers in the drum often require replacement.

Persistent failures after these steps signal deeper electrical faults. Schedule professional maintenance to avoid further damage—especially if you smell burning or hear buzzing near circuit panels.

Key Troubleshooting Steps for Electrical Failures

When your trusted equipment stops working, electrical faults are often the hidden culprit. Follow these targeted steps to isolate wiring issues and restore functionality efficiently.

Testing the Power Cord and Outlet

Start by examining the power cord for cuts or exposed wires. Bend it gently near the plug—cracks here often disrupt current flow. Plug a lamp into the same outlet to confirm it’s active.

| Issue | Test Method | Solution |

|---|---|---|

| Loose Plug | Wiggle cord while plugged in | Replace damaged cord |

| Dead Outlet | Test with phone charger | Reset breaker or call electrician |

| Burnt Smell | Inspect socket for discoloration | Discontinue use immediately |

Diagnosing Fuse and Breaker Issues

Locate your home’s electrical panel. A tripped circuit breaker sits between on/off positions. Flip it fully off before resetting. For fuse boxes:

- Remove suspect fuse

- Check glass casing for black residue

- Replace with same-amperage fuse

If your dryer trips breakers during heating cycles, the heating element might be faulty. Persistent failures after these checks mean it’s time to contact professional help. Complex repairs often require certified technician expertise.

Diagnostic Tips for Mechanical and Component Failures

Mechanical failures often reveal themselves through unusual noises or inconsistent performance. While electrical issues tend to cause complete shutdowns, component problems may let your device start before failing mid-cycle. Focus on parts that endure the most wear—like motors and heating systems.

Inspecting Motors, Heating Elements, and Switches

Start by unplugging the unit and removing access panels. Look for:

- Burnt smells near motors—a sign of overheating

- Loose belts in dryers or washing machines

- Corrosion on heating elements in ovens or dishwashers

Test switches with a multimeter set to continuity mode. If there’s no response when toggling, the switch likely needs replacement. For motors, spin the drum manually. Resistance or grinding noises indicate worn bearings.

“Always compare your findings to the manual’s resistance values,” advises a certified technician. “Deviations of more than 10% signal component failure.”

Check heating coils for cracks or breaks. In dryers, a faulty thermal fuse—often caused by clogged vents—will stop heat production. Replace these parts using manufacturer-approved replacements.

If tests show functional components but the problem persists, internal wiring or control board failures might be at play. This is the time to contact professional repair services. Complex mechanical issues often require specialized tools and expertise.

Inspecting and Testing Internal Appliance Components

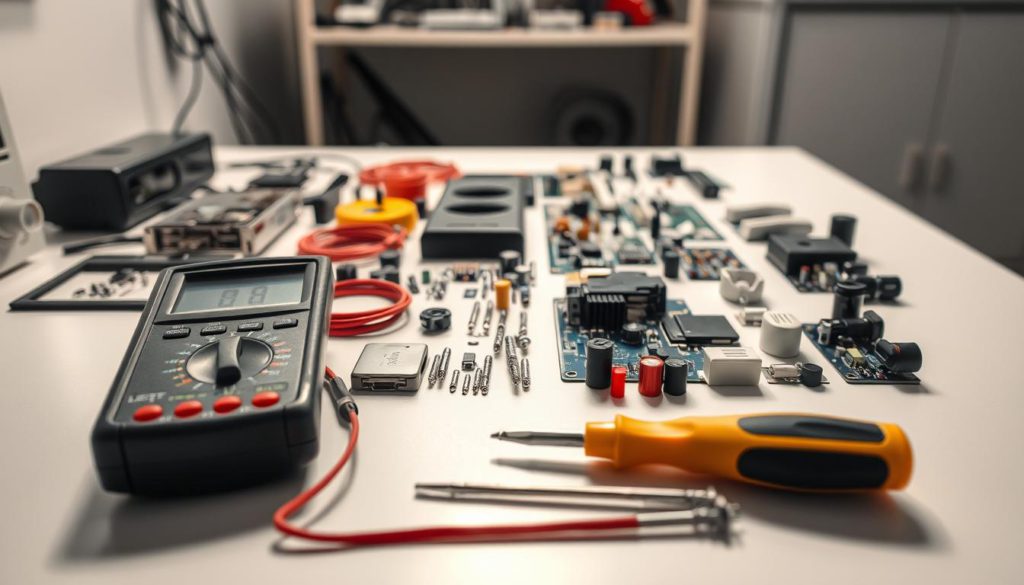

Your toolkit holds the key to solving mysterious appliance failures. With a multimeter and basic safety know-how, you can uncover hidden electrical gremlins affecting your devices. Let’s explore how to safely test internal parts for faults.

Mastering Multimeter Basics

Start by consulting your appliance’s manual to locate test points for switches, motors, and heating elements. Set your multimeter to voltage mode to check live circuits or continuity mode for disconnected components. For example:

| Component | Test Type | Normal Reading |

|---|---|---|

| Door Switch | Continuity | 0-1 Ohms |

| Heating Element | Resistance | 20-50 Ohms |

| Motor Windings | Voltage | 120V (US standard) |

When testing dryer components like thermal fuses, make sure the unit is unplugged. Place multimeter probes on both ends of the fuse—a reading of “OL” means it’s blown. For motors, check for steady resistance values between terminals.

“Always verify the manual’s recommended voltage ranges,” advises a certified technician. “Even minor deviations can indicate failing parts.”

Focus on high-wear components first. In dryers, test the door latch switch and belt tension. For kitchen appliances, inspect heating coils and control boards. Replace cracked wires or corroded connectors immediately.

Remember to wear insulated gloves when handling live circuits. If you encounter complex wiring diagrams or inconsistent readings, contact professional repair services. Electrical systems demand precision—don’t risk improper repairs.

Preventative Maintenance and Regular Checks

Proactive care keeps your household helpers running smoothly. Simple routines can add years to your equipment’s lifespan while preventing 60% of common failures. Start with these essential practices to maintain peak performance.

- Vacuum refrigerator coils to prevent motor strain

- Inspect washing machine hoses for cracks or water leaks

- Clear dryer vents of lint buildup

- Test outlet stability by gently wiggling plugs

Seasonal tasks matter too. Every six months:

- Check door seals with the dollar bill test

- Flush heating systems in coffee makers

- Inspect dishwasher spray arms for clogs

“Three minutes of monthly maintenance can prevent three hours of emergency repairs,” notes a home service technician.

Your manual specifies lubrication points and filter replacement schedules. Mark these dates on your calendar. For gas appliances, annual professional service ensures safety and efficiency.

These habits reduce repair costs by 40% on average. Address minor issues before they become major problems—your future self will thank you.

When to Call a Professional Repair Technician

Some failures demand more than a quick fix. If basic troubleshooting hasn’t resolved the issue, persistent symptoms often indicate complex internal problems. Knowing when to step back protects your safety and prevents costly mistakes.

Recognizing Warning Signs and Persistent Faults

Watch for these red flags:

- Recurring tripped breakers when using specific units like your dryer

- Loud grinding noises from the motor area

- Error codes that resetting won’t clear

Burnt smells near vents or sparking outlets require immediate attention. For gas appliances, hissing sounds or gas odors mean shut off the supply and contact professional help immediately.

| Symptom | Risk Level | Action |

|---|---|---|

| Breaker trips daily | High | Call electrician |

| Dryer overheats | Moderate | Clear vents first |

| Control panel dead | Moderate | Schedule repair |

“Homeowners often overlook minor symptoms until they escalate,” says licensed technician Marco Rivera. “Early intervention saves $300+ on average.”

Choose certified repair services with warranties on parts and labor. Reputable companies explain costs upfront and provide written estimates. For critical systems like electrical panels or gas lines, never delay professional assistance.

Conclusion

A non-responsive household device can test your patience, but methodical checks often reveal simple solutions. Always begin with safety and power supply verification—confirm outlets work and cords show no damage. For dryers, inspect vents for lint buildup that might trigger shutdowns.

Move to internal components only after ruling out basic issues. A multimeter helps test switches and heating elements efficiently. Reference your manual for model-specific guidance—many manufacturers list error codes and reset protocols.

Preventative care extends equipment life. Clean dryer filters after each cycle and schedule annual inspections for motors and belts. Address minor quirks promptly to avoid costly breakdowns.

When troubleshooting stalls or risks emerge, contact certified technicians. Complex electrical faults in dryers or persistent tripped breakers demand professional expertise. Timely repairs paired with routine maintenance keep household helpers running smoothly for years.

FAQ

How do I confirm if my device is properly connected to power?

Check if the plug is fully inserted into the outlet. Test the outlet with another gadget, like a lamp, to verify it’s functional. Ensure the circuit breaker isn’t tripped or the fuse blown.

What should I do if the circuit breaker keeps tripping?

Unplug the machine and reset the breaker. If it trips again, there may be a short circuit or overload. Avoid repeated resets—this risks damage. Contact a certified technician for inspection.

Why won’t my dryer start even after passing basic checks?

Inspect the door switch for damage or misalignment. A faulty motor or broken belt could also prevent the drum from spinning. Refer to the manual for testing steps or schedule professional repairs.

How can I test a heating element for faults?

Use a multimeter to check for continuity. If the reading shows infinite resistance, the element is defective. Replace it with manufacturer-approved parts to ensure safety and compatibility.

When should I stop DIY fixes and call a technician?

If issues persist after basic troubleshooting, or you notice burning smells, sparks, or water leaks, shut off the device immediately. Complex repairs involving wiring or gas lines require licensed expertise.

What routine maintenance prevents sudden power failures?

Clean vents, filters, and coils regularly to avoid obstructions. Inspect cords for fraying and test outlets annually. Schedule professional servicing every 1–2 years for high-use units like refrigerators or HVAC systems.

Can a faulty switch cause a microwave to stop working?

Yes. Door or control panel switches often fail due to wear. Use a multimeter to test continuity. If broken, replace the switch using OEM parts to maintain safety standards.