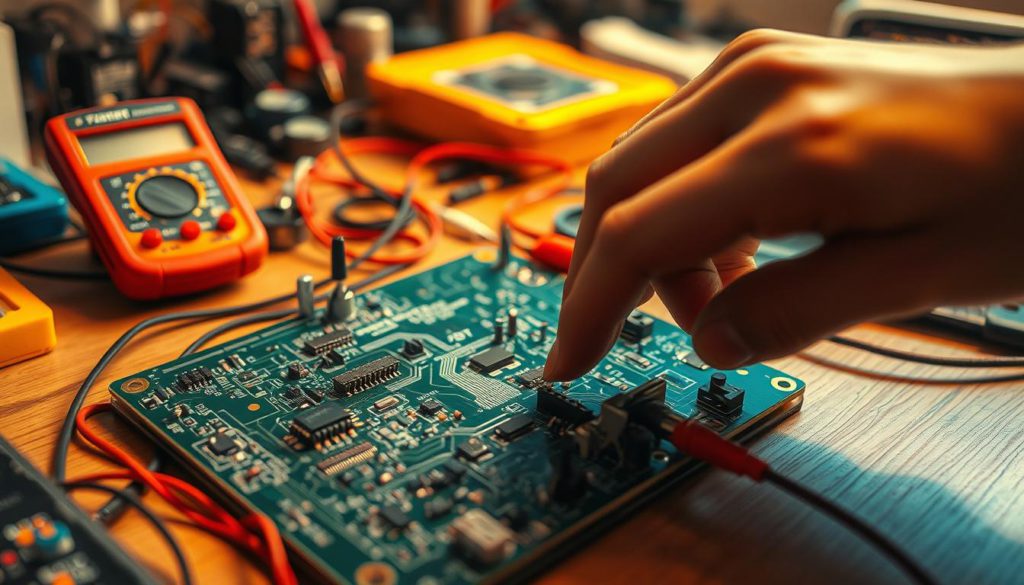

Ever tried fixing a gadget only to realize you’re missing half the equipment needed? You’re not alone. Many DIY enthusiasts and professionals alike struggle with assembling an affordable yet effective toolkit for electronics repairs. The truth is, you don’t need expensive gear to handle most projects—just the right essentials.

- Introduction to Electronics Repair

- Understanding Your Electronics Repair Needs

- Essential Safety Measures for Electronics Repairs

- Top 10 Must-Have Tools for Basic Electronics Repairs

- Setting Up Your Electronics Repair Workbench

- Selecting the Right Soldering Equipment

- Essential Hand Tools: Screwdrivers, Nut Drivers, and Allen Keys

- Mastering Pliers, Wire Strippers, and Cutting Tools

- Advanced Soldering Tools and Accessories

- Prototyping and Testing Equipment for Electronics

- Digital Tools for Advanced Diagnostics

- Effective DIY Troubleshooting Techniques

- Tool Maintenance and Best Practices

- Budget-Friendly Tips for Building Your Tool Kit

- Where to Find Quality Electronics Repair Tools

- Conclusion

- FAQ

This guide simplifies your journey. Whether you’re troubleshooting a circuit board or replacing smartphone components, having core items on hand saves time and frustration. We’ll walk through budget-friendly options that deliver professional results, along with tips for organizing your workspace and staying safe.

You’ll discover how a well-curated selection of equipment can tackle 90% of common issues. From precision screwdrivers to multimeters, each tool serves a purpose. We’ve also included strategies for diagnosing problems faster, so you spend less time guessing and more time fixing.

Key Takeaways

- Affordable tools can handle most electronics repairs effectively

- Safety measures prevent accidents during DIY projects

- Proper workspace setup boosts efficiency

- Diagnostic tools simplify troubleshooting

- This resource applies to hobbyists and professionals alike

Introduction to Electronics Repair

In today’s DIY world, fixing gadgets is a skill everyone can master. Whether you’re replacing a phone battery or fixing a gaming console, understanding electronics starts with knowing how components interact within a circuit. Modern devices rely on these tiny parts to function, and learning their roles helps you diagnose issues faster.

Soldering is the backbone of most repair work. It creates permanent connections between components, ensuring your fixes last. Beginners often struggle with overheating parts or weak joints—that’s why investing time to practice matters. Start with low-cost kits to build confidence before tackling complex circuit boards.

Here’s a quick breakdown of common tools and their roles:

| Tool | Primary Use | Skill Level |

|---|---|---|

| Soldering Iron | Joining metal parts | Beginner+ |

| Multimeter | Testing voltage/resistance | Intermediate |

| Tweezers | Handling small components | All Levels |

Safety is non-negotiable. Always wear anti-static wristbands when handling sensitive electronics, and keep a fire-resistant mat nearby during soldering sessions. Later sections will dive deeper into workspace setup and advanced troubleshooting for intricate circuit issues.

Understanding Your Electronics Repair Needs

Your toolkit isn’t one-size-fits-all. Whether you’re tinkering with a smartphone or building custom circuits, your projects demand tools that align with your skill level and goals. Start by asking: What devices do I fix most often? and How complex are my tasks? This clarity helps avoid overspending on unnecessary gear.

User Profiles: Beginner, Creator, and Service

Beginners need simplicity. A basic set with a 30-watt soldering iron, precision screwdrivers, and needle-nose pliers covers most repairs. Focus on learning proper techniques before upgrading.

Creators prioritize versatility. They often pair a temperature-controlled soldering iron with wire strippers and a multimeter for prototyping. Modular tools adapt to diverse projects.

Service professionals require speed and reliability. Heavy-duty irons, ESD-safe tweezers, and diagnostic tools dominate their kits. Durability matters for daily use.

Skill Levels and Project Goals

Match your tools to your ambitions. Simple fixes like replacing phone batteries demand less precision than micro-soldering GPU chips. For example, a $20 iron works for basic connections, but temperature-adjustable models handle delicate device components better.

Before buying new gear, audit your current set. Identify gaps like missing hex keys or inadequate wire cutters. Upgrading strategically saves money and workspace clutter.

Essential Safety Measures for Electronics Repairs

Working with delicate components requires more than skill—it demands respect for invisible threats. Static electricity can destroy sensitive parts before you finish your first solder joint. A single spark from your fingertip carries enough charge to fry modern circuits.

Grounding Yourself Against Disaster

Anti-static wrist straps aren’t optional. Clip yours to a grounded metal surface before touching any components. Pair it with a conductive mat to create a safe zone on your workbench. One study found ESD causes 35% of unexplained device failures—protection pays off.

Handle wire strippers and other metal instruments carefully. Wipe them down with isopropyl alcohol to remove residue. Dull blades force you to press harder, increasing slip risks. As one technician notes:

“Clean tools make clean repairs—rusty pliers belong in museums, not your toolkit.”

| ESD Protection Method | Effectiveness | Cost |

|---|---|---|

| Wrist Straps | High | $5-$20 |

| Grounding Mats | Essential for workbenches | $15-$50 |

| Anti-Static Bags | Component storage only | $0.10-$2 each |

When heating solder, position your iron’s tip away from flammable materials. Use fume extractors or work near open windows—lead-free alternatives reduce toxicity but still emit irritants. Your equipment’s quality matters less than how you use it. A $200 multimeter won’t save a circuit you zapped with static.

Top 10 Must-Have Tools for Basic Electronics Repairs

Assembling the right gear transforms frustrating repairs into smooth fixes. Your success hinges on having specific equipment that handles delicate components and tight spaces. Let’s break down the critical items every workspace needs.

Precision screwdrivers top the list. They tackle everything from smartphone disassembly to adjusting circuit board screws. Magnetic tips prevent tiny fasteners from disappearing mid-repair. Brands like iFixit offer color-coded sets for quick identification.

Needle-nose pliers grip stubborn wires or bend leads without slipping. Pair them with flush cutters for trimming excess solder. A quality set lasts years—Engineer brand models are praised for their durability in professional forums.

- Wire strippers: Adjustable blades handle 20-30 AWG sizes safely

- Nut drivers: Magnetic hex bits secure motherboard standoffs

- Tweezers: ESD-safe options prevent static damage during PCB work

Hakko’s FX-888D soldering station dominates workshop conversations for its temperature stability. Combine it with desoldering braid to clean up messy joints. Multimeters like AstroAI’s budget model verify voltage and continuity in seconds.

| Tool | Key Benefit | Ideal For |

|---|---|---|

| Soldering Iron | Precise heat control | Circuit board repairs |

| Multimeter | Diagnostic accuracy | Troubleshooting shorts |

| Tweezers | Component placement | SMD soldering |

A complete set eliminates mid-project store runs. Organize tools in labeled compartments—chaos wastes time and risks losing critical pieces. Regular maintenance, like cleaning cutter blades with alcohol wipes, ensures peak performance.

Techs at uBreakiFix emphasize:

“Invest in comfort. Ergonomic handles reduce hand fatigue during hour-long repairs.”

Your toolkit evolves with experience, but these essentials handle 80% of household electronics issues from day one.

Setting Up Your Electronics Repair Workbench

Your repair space isn’t just a table—it’s mission control for every project. A dedicated workbench minimizes distractions and keeps critical tools within arm’s reach. Start by anchoring a metal surface to your workspace; its conductive properties reduce static buildup while handling circuit boards.

Position frequently used components like power supplies and test leads on your dominant side. Store spare resistors and capacitors in labeled trays above the bench. This layout prevents accidental spills and speeds up part retrieval during complex repairs.

Integrate a regulated power supply with overload protection. Stable voltage prevents fried components when testing prototypes. Pair it with surge-protected outlets—cheap power strips risk damaging sensitive equipment during voltage spikes.

| Workbench Feature | Purpose | Recommended Setup |

|---|---|---|

| Surface Material | Static dissipation | Grounded metal sheet |

| Tool Storage | Quick access | Magnetic strips + pegboard |

| Lighting | Precision visibility | Adjustable LED lamp |

Add a rotary tool with grinding and polishing attachments. It tackles tasks from trimming plastic casings to smoothing rough solder joints. Professionals at iFixit note:

“A multitasking tool saves 15+ minutes per repair versus switching between single-use devices.”

Wipe down your metal surface after each session to remove solder debris. Secure loose wires with adhesive clips—tangled cords cause trips and yank components off the board. These habits transform chaotic workspaces into efficient repair hubs.

Selecting the Right Soldering Equipment

Choosing the best soldering tools feels like solving a puzzle—until you know which pieces matter most. Your projects demand precise heat management and tip flexibility to avoid damaging components. Let’s simplify your options.

Soldering Iron Options and Features

Basic soldering irons work for occasional repairs. They plug directly into outlets without temperature adjustments. However, models with adjustable controls let you dial in heat settings for different wire gauges and board types.

Interchangeable tips expand functionality. Conical shapes handle detailed work, while chisel tips spread heat evenly for larger joints. Look for irons with at least three tip options. Brands like Weller and Hakko offer kits with 5+ specialized designs.

Soldering Station vs. Standalone Irons

Stations provide superior power consistency. Their separate base units regulate heat better than standalone models. This prevents overheating delicate circuits. Stations also include holders and sponges for safer operation.

Compare key differences:

| Feature | Station | Standalone |

|---|---|---|

| Temperature Control | Precise adjustments | Fixed or limited |

| Tip Variety | 10+ options | 2-3 included |

| Power Supply | Stable output | Fluctuates under load |

Frequent users should invest in stations. As a Hakko engineer notes:

“Consistent heat equals reliable joints. Stations maintain 1% temperature accuracy—critical for repeat repairs.”

Match your iron type to project frequency. Occasional hobbyists save with basic tools, while daily repairs justify station costs.

Essential Hand Tools: Screwdrivers, Nut Drivers, and Allen Keys

Precision in electronics repair starts with the right grip—literally. Your hand tools determine whether you strip a screw or remove it cleanly. From opening device casings to adjusting circuit board mounts, these essentials bridge the gap between frustration and flawless execution.

Screwdrivers & Precision Tools

Not all screwdrivers are created equal. Phillips #000 and Torx T5 bits dominate smartphone and laptop repairs. Magnetic tips prevent tiny screws from vanishing into carpets—a lifesaver when reassembling devices. Brands like Wiha and iFixit offer anti-slip handles for better control in tight spaces.

Consider these types for different tasks:

| Type | Use Case | Recommended Brand |

|---|---|---|

| Precision Phillips | Consumer electronics | iFixit Mako |

| Torx Security | Tamper-proof screws | Wiha 75992 |

| Flathead | Prying battery connectors | Hakko CHP-170 |

Nut Drivers and Hex (Allen) Keys

Magnetic nut drivers simplify motherboard standoff installations. Unlike pliers, they apply even pressure to prevent thread damage. For hex screws in 3D printers or drones, Bondhus ball-end keys reach angled fasteners without stripping.

A complete set should include:

- 1.5mm-4mm hex keys (common in European devices)

- 5/64” and 1/8” nut drivers (standard for US-made electronics)

- Color-coded organizers (prevents mix-ups during repairs)

As noted by a Micro Center technician:

“Invest in a 32-piece kit. You’ll have the right tool for 95% of jobs without buying extras.”

Mastering Pliers, Wire Strippers, and Cutting Tools

The difference between a botched repair and a flawless fix often lies in your grip. Choosing the right pliers prevents bent pins and cracked components. Needle-nose variants excel at positioning tiny resistors, while flat-nose models twist wires without slippage.

For stripping insulation, wire strippers with adjustable gauges outperform generic cutters. Set the blade depth to match your wire thickness—too deep risks slicing copper strands. Rotate the tool 180 degrees before pulling to ensure clean removal.

Proper Handling Techniques for Accuracy

| Tool Type | Best Use | Common Mistakes |

|---|---|---|

| Long-Nose Pliers | Bending leads | Over-tightening |

| Flush Cutters | Trimming solder | Angling blades |

| Self-Adjusting Strippers | Multi-gauge wires | Ignoring wear indicators |

Always position cutters perpendicular to the wire. Angled cuts leave sharp edges that pierce insulation. For stranded cables, lightly twist strands before stripping to prevent fraying.

A Milwaukee Tool technician advises:

“Replace blades when cuts require excessive force. Dull tools cause more accidents than steady hands ever will.”

Store pliers with jaws slightly open to maintain spring tension. Wipe metal surfaces after each use—corrosion ruins precision. These habits keep your toolkit reliable through hundreds of repairs.

Advanced Soldering Tools and Accessories

When standard equipment can’t handle intricate joints, specialized gear becomes your best ally. High-performance tasks demand tools that balance heat control with ergonomic design. Professional-grade soldering irons offer adjustable temperatures from 200°C to 480°C, adapting to everything from thin wires to thick ground planes.

Hot air stations revolutionize rework. They let you remove multi-pin components without damaging nearby elements. Pair them with micro-tweezers for precise placement of surface-mount parts. Unlike basic irons, these systems prevent cold joints through consistent airflow regulation.

Consider these upgrades for your toolkit:

- Desoldering pumps that clear old solder in one click

- ESD-safe tweezers with non-magnetic tips

- Temperature-controlled stations with replaceable nozzles

| Feature | Entry-Level | Advanced |

|---|---|---|

| Heat Recovery | 3-5 seconds | <1 second |

| Tip Options | 3-5 types | 15+ specialized |

| Warranty | 90 days | 2-5 years |

Precision matters most when working with microchips. A 0.2mm tip prevents bridging between pins spaced 0.5mm apart. As Hakko engineers advise:

“Upgrade your equipment when projects require sub-millimeter accuracy—consumer-grade tools lack the thermal stability.”

Maintain your soldering iron with brass wool instead of wet sponges. This preserves tip coatings and extends lifespan. Match accessories to your most frequent tasks—specialized gear pays for itself in saved time and flawless results.

Prototyping and Testing Equipment for Electronics

Prototyping bridges ideas and working circuit designs faster than you think. Whether testing a new sensor configuration or debugging a power supply issue, temporary setups let you experiment without permanent changes. This flexibility saves hours compared to soldered prototypes.

Breadboards and Jumper Wire Essentials

A quality board forms the foundation. Standard 830-tie point models handle most small-scale projects. For complex circuit simulations, modular boards link together. Color-coded rows and columns prevent connection errors during assembly.

Jumper wires come in three types:

- Pre-cut: Ideal for fixed layouts (22-28 AWG)

- Flexible: Bend around components without slipping

- Test leads: Pair with multimeters for live measurements

| Breadboard Type | Size | Best For |

|---|---|---|

| Standard | 6.5″ x 2.1″ | Basic IC testing |

| Mini | 3.3″ x 2.0″ | Portable projects |

| Modular | Expandable | Multi-stage systems |

Keep a set of wire strippers nearby. They prepare custom jumpers from spare 22-gauge cables. Label each strand’s length—consistent sizing reduces clutter. As Arduino forum users note:

“Organized jumpers cut debugging time by 40% compared to tangled nests.”

For repeated trials, use gold-plated connectors. They withstand hundreds of insertions without corrosion. Pair them with a regulated power supply—variable voltage settings prevent component damage during initial tests.

Digital Tools for Advanced Diagnostics

Diagnosing modern electronics requires more than a keen eye—it demands smart tools that reveal hidden issues. Advanced instruments like multimeters and oscilloscopes act as your eyes inside circuit behavior, exposing problems invisible during visual inspections. These devices transform guesswork into data-driven solutions.

Multimeters and Oscilloscopes in Practice

A digital multimeter checks power levels, continuity, and resistance in seconds. For example, testing a USB port’s voltage confirms if it delivers the required 5V. Oscilloscopes go deeper, showing how signals change over time—critical for spotting glitches in audio circuits or microcontroller outputs.

| Tool | Primary Use | Skill Level |

|---|---|---|

| Multimeter | Voltage/resistance checks | Beginner+ |

| Oscilloscope | Signal analysis | Advanced |

Build a versatile set with both tools. Entry-level models handle most household repairs, while professional-grade devices manage complex automotive or industrial systems. As a Fluke engineer notes:

“Matching the type of tool to your project’s demands prevents overspending and underperformance.”

When selecting equipment, prioritize auto-ranging multimeters—they adjust settings automatically, reducing errors. For oscilloscopes, 50MHz bandwidth suits basic circuit work. Keep probes organized; tangled wires lead to inaccurate readings.

Effective DIY Troubleshooting Techniques

Ever powered up a device only to face mysterious glitches? Troubleshooting electronics requires a methodical way of isolating issues without causing collateral damage. Start by visually inspecting the circuit board for burnt marks or loose connections—these often reveal the root cause.

Diagnosing Circuit Failures

Use a multimeter to check voltage at key test points. Compare readings against your device’s specifications. If a circuit shows no power, trace backward from the faulty component to identify breaks in continuity.

| Tool | Diagnostic Use | Accuracy Level |

|---|---|---|

| Multimeter | Voltage/continuity checks | ±2% |

| Logic Analyzer | Signal pattern detection | Microsecond precision |

For intermittent failures, gently flex the board while powered on. Intermittent connections often react to physical stress. Document each step—systematic elimination speeds up repairs.

Repair Strategies for Beginners

Start with low-risk projects like replacing capacitors or reflowing cold solder joints. Use a magnifying glass to maintain precision when handling tiny components. If a joint looks dull or cracked, apply fresh soldering flux and reheat it briefly.

Keep a “sacrificial” circuit board for practice. Remove and resolder parts repeatedly to build muscle memory. As one repair instructor advises:

“Treat every repair like a science experiment—change one variable at a time and observe results.”

When reassembling devices, photograph each step. This creates a visual roadmap if you need to backtrack. Most projects fail from rushed execution, not lack of skill.

Tool Maintenance and Best Practices

Your tools work hard—show them some love. Regular upkeep keeps them performing like new and prevents mid-repair breakdowns. Let’s explore simple habits that protect your investment and ensure precision.

Regular Cleaning and Calibration

Wipe down pliers and cutters after each use. Residue from adhesives or solder accelerates rust. For wire strippers, apply a drop of sewing machine oil to pivot points monthly.

Soldering iron tips need special care. Use brass wool to remove oxidation, not abrasive sponges. Calibrate your iron’s temperature weekly with a thermocouple—a 50°F drift can ruin sensitive components.

| Tool | Maintenance Task | Frequency |

|---|---|---|

| Multimeter | Test probe continuity | Before each use |

| Power Supply | Dust vents with compressed air | Monthly |

| Screwdrivers | Sanitize handles | After sticky projects |

Proper Storage and Care Tips

Store tools in labeled trays—not loose in drawers. Magnetic strips keep frequently used items visible. For glue bottles, seal lids with plastic wrap to prevent drying.

Repair cracked handles instantly. A dab of epoxy glue reinforces grips better than tape. As noted by a Milwaukee Tool engineer:

“Treat your tools like surgical instruments. Clean, dry, and organized storage adds years to their lifespan.”

- Use silica gel packs in storage cases

- Hang soldering irons vertically

- Store tips separately to avoid scratches

Budget-Friendly Tips for Building Your Tool Kit

Building a reliable toolkit doesn’t require emptying your wallet—just smart planning. Start with a core set of tools that handle 80% of common projects. Prioritize versatile items like a 30-watt soldering iron and adjustable wire strippers. These work across multiple repairs, delaying the need for specialized gear.

Compare prices aggressively. Online marketplaces often undercut brick-and-mortar stores for identical tools. Sign up for price alerts on sites like Honey or CamelCamelCamel to catch discounts. As one Reddit user notes:

“I saved 40% on a multimeter by waiting for a flash sale—patience pays.”

Expand your set gradually. Buy screwdrivers first, then add niche items like IC extractors as projects demand. This staggered approach prevents overspending on rarely used tools. Check local electronics shops for open-box deals—many offer warranties on returned items.

| Tool Type | Budget Option | Premium Option | When to Choose |

|---|---|---|---|

| Soldering Iron | $15 fixed temp | $90 adjustable | Advanced repairs |

| Multimeter | AstroAI AM33D | Fluke 101 | Professional use |

| Screwdriver Set | 12-piece generic | iFixit Mako | Daily repairs |

Read reviews critically. Focus on verified purchases and watch for consistent complaints about durability. A $10 choice that breaks after three uses costs more than a $25 reliable pick. Trade communities like Facebook Marketplace are goldmines for lightly used equipment—just test before buying.

Remember: a budget-friendly choice isn’t about cheapness—it’s strategic value. Invest where quality matters (soldering tips), and save on single-use items. Your toolkit grows smarter, not bigger.

Where to Find Quality Electronics Repair Tools

Finding reliable tools for electronics repairs starts with knowing where to look. Specialty stores like Micro Center offer hands-on testing stations and expert advice—ideal for choosing equipment like precision screwdrivers. Online retailers provide wider selections, with Amazon and Newark leading in rotary tool variety and fast shipping.

Compare big-box stores against niche suppliers. While Home Depot stocks basic wires and glue, shops like Adafruit specialize in SMD rework stations and conductive adhesives. Check return policies: specialty vendors often provide better warranties on supply items.

| Vendor Type | Best For | Example Vendors |

|---|---|---|

| Local Hardware | Urgent replacements | Ace Hardware, True Value |

| Online Marketplaces | Price comparisons | Digi-Key, eBay |

| Specialty Electronics | Expert-grade tools | SparkFun, Mouser |

Read customer reviews focusing on equipment durability. Look for phrases like “500+ solder joints without tip degradation.” For rotary accessories, verify RPM compatibility with your existing tools. A Reddit user advises:

“Order sample wires first—thickness varies between brands despite identical specs.”

Quality supply chains matter. Industrial adhesives from 3M outperform dollar-store glue in heat resistance. Partner with vendors offering batch testing certificates for critical components. This upfront effort prevents project delays and repeat purchases.

Conclusion

Mastering electronics repairs begins with understanding your tools—and trusting your skills. With the right instruments, from precision screwdrivers to reliable rotary tools, you transform frustration into accomplishment. Each repair becomes a chance to deepen your knowledge of circuit boards and power supply systems.

Quality equipment makes working electronics projects safer and more efficient. Sharp wire cutters slice through insulation cleanly, while ergonomic pliers protect your hands during delicate tasks. Remember: proper maintenance extends tool lifespan—wipe down metal surfaces and store components in dry conditions.

Apply the troubleshooting techniques shared here to diagnose issues faster. Whether testing connections or replacing wires, methodical control prevents costly mistakes. Your toolkit evolves with experience, adapting to new challenges in creative ways.

Every successful repair starts with preparation. Assemble your essentials, practice safety protocols, and embrace the learning process. You’ve got this—one steady project at a time.

FAQ

What safety gear is essential for electronics repairs?

Always use an anti-static wrist strap to prevent electrostatic discharge (ESD). ESD-safe mats and insulated gloves add extra protection. Brands like Hakko and 3M offer reliable options for beginners and professionals.

How do I choose between a soldering station and a standalone iron?

Soldering stations (e.g., Weller WE1010) provide adjustable temperature control, ideal for precision work. Standalone irons like the Hakko FX888D suit occasional use. Match your choice to project complexity and frequency.

What screwdriver types are necessary for small devices?

Precision screwdrivers with Phillips, flathead, and Torx tips are critical. Brands like iFixit or Klein Tools offer magnetized sets for handling tiny screws in phones, laptops, or circuit boards.

Can I use regular pliers for electronics work?

No. Use needle-nose pliers for tight spaces and flush cutters for trimming wires. Channellock or Engineer PA-09 models ensure clean cuts without damaging components.

Why are wire strippers important for beginners?

Strippers like the Irwin Vise-Grip auto-adjust to insulation thickness, preventing accidental cuts to copper strands. They’re faster and safer than using knives or scissors.

Do I need a multimeter for basic repairs?

Yes. A Fluke 101 or AstroAI DM6000 measures voltage, continuity, and resistance. It’s indispensable for diagnosing circuit failures or testing batteries.

How often should I clean my soldering iron tip?

Clean the tip with a brass sponge after each use to remove oxidation. Apply fresh solder before storage to prolong its lifespan. Tinned tips conduct heat better.

Are breadboards necessary for prototyping circuits?

Yes. Breadboards let you test designs without soldering. Jumper wires and ICs snap into place, making revisions easy. Brands like Elegoo offer reusable boards for hobbyists.

What’s a budget-friendly way to start a tool kit?

Prioritize basics: a 30W soldering iron, screwdriver set, and multimeter. Kits from Anbes or Plusivo include these at under . Upgrade tools as your skills advance.

Where can I find durable electronics repair tools?

Specialty retailers like Adafruit or SparkFun stock quality brands. For hand tools, Amazon Basics or Tekton offers affordable yet reliable options with warranties.